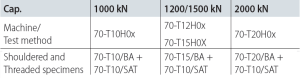

Max. test load

- In tension: 1000 kN

- In compression: 2000 kN

Measurement load ranges :Automatic changeover of scale sensitivity, minimum reading value 100 N

Tensile test

- Max. distance between grips: 700 mm

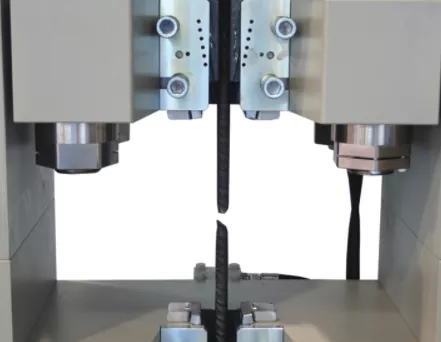

- Gripping system: Hydraulic with remote control

- Max. round dia.: 40 mm

- Max. plate specimens size: 70×35 mm

Test speed: 0-100 mm/min

Crosshead adjustment speed: 500 mm/min

Max. piston stroke: 610 mm

Distance between columns: 330 mm

HPU POWER AND CONTROL CONSOLE

Hardware

- 131.000 points effective resolution

- Control frequency 250 Hz

- Sampling rate 500 Hz

- Closed-loop P.I.D.control

- 6 channels (one dedicated to crosshead displacement) to measure elongation/displacement/strain with potentiometric, conditioned LVDT and magnetostrictive transducers

- 4 channels for strain measurements with strain gauges

- 2 channels for load sensors: load cell and load cell/pressure transducer of possible second frame

- simple multi-sensors connection and calibration file selection

- digital linearization of the calibration curve. (multi-coefficient)

Hydraulics

- Dual stage pump: centrifugal low pressure for fast approach (max. flow rate 9 l/min ) automatically switching to radial multi- piston high pressure (max. flow rate 3.2 l/min) for loading

- Oil flow control by servo-controlled proportional valve

- AC motor 3000 W

- Maximum working pressure 700 bar

- Oil temperature controlled by air cooling system

- Console cabinet lined with soundproofing material for operator’s comfort.

- Tank capacity: 30 liters

MANAGEMENT SOFTWARE AND SOFTWARE PACKAGES

The machine is supplied complete with RTM (Real Time Management) user interface environment allowing:

- Remote control of the complete system for automatic test execution: quick platen approach, zeroing, test execution according to the selected test type, calculation of results, graphical and numerical management of results

- Storage of single and multiple tests

- Printing of customized test reports for both single and multiple tests

- Real time and deferred management of tests data and results, either in numeric or in graphic format

- Language selection (Latin characters only)

- Units selection

- Remote technical assistance/diagnostic via internet

The following Software packages are also included in the system:

- UTS Software Specifically designed for tensile testing under load/stress control and crosshead separation control (by using the displacement transducer supplied with the machine), allowing:

- Simultaneous display of stress/time, stress/elongation %, elongation/time and stress/elongation;

- Possibility to overlap two elongation/stress graphs: one obtained with the included displacement transducer measuring crosshead separation travel and the other obtained w ith an optional extensometer (coaxial or universal);

- Elaboration of tension test results: ReH, ReL or Rp (calculated at three different elongation percentages selectable by the user), A, Ag, At, Agt, Ae, Rt, Z, elastic modulus E, etc, conforming to EN ISO 6892-1 and EN 15630-1 for steel rebars.

- DATAMANAGER Software For compression, flexure and indirect tensile test on concrete, cement specimens and other construction materials allowing:

- Real time monitoring of test data and stress/time graph

- Automatic load detection failure and storage

- Cement testing to EN 196-1 guided test procedure

- Saving of batch file with automatic calculation of average and standard deviation

The following software package is available as option when upgrading the machine with the hydraulic system for a second frame connection (see 70-T10/2F).

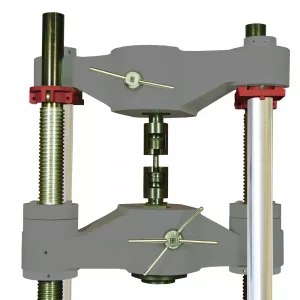

- E-MODULE software For Poisson ratio and Elastic Modulus determination on concrete specimens allowing:

- Free unlimited programmable load/stress cycles to fulfill any kind of test procedure

- Real time monitoring of test data, stress/time, stress/axial strain, stress/lateral strain graphs

- Automatic verification of sample centering and sensors functionality, as per Standard requirements

- Automatic calculation of Initial and Final secant Elastic Modulus values

DIMENSIONS

- Testing frame (piston fully out): 955x635x3960 mm

- Control console: 800x900x1550 mm

WEIGHTS AND SHIPPING CUBAGE

- Testing frame: 2900 kg approx.

- Control console: 200 kg approx.

- Total gross weight: 4000 kg approx.

- Shipping cubage: 7 m3 approx.

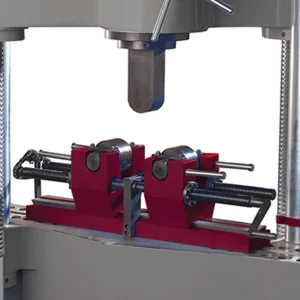

Shearing motion: Electromechanically driven at 4°

Shearing motion: Electromechanically driven at 4°