Specimen preparation and ultimately specimen quality are critical factors in material characterization. IPC Global’s Multi Core-Drill is a superior laboratory asphalt core drill whose robust and rigid design provides a precise coring of asphalt prisms, cylindrical and slab samples to the highest quality.

The Multi Core-Drill has been designed to be easy to use, flexible and adaptable providing users with precise drilling capabilities. This will enable users to have absolute confidence in the quality of their specimens and the reliability of their test results.

Designed, in particular, for coring samples 100 mm dia., 150 mm high for Dynamic Modulus (AMPT, AASHTO TP79) and 38 to 75 mm high for Indirect Tensile Tests (EN 12697-24 and 26) coming, as example, from Gyratory compactors.

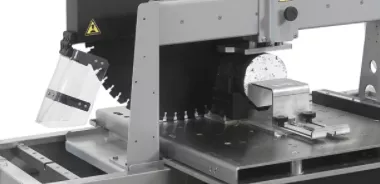

Included as standard the Multi Core-Drill comes with the support and clamping devide that sits inside the stainless steel tray and ensures asphalt samples produced by IPC Global’s PReSBOX are held firm and in the correct position for drilling.

The Multi Core-Drill can also be provided with an optional device which allows for up to 80 mm transversal movement of the drill for parallel coring. This device, in combination with the longitudinal movement of the carriage, ensures high cutting alignment and increases the number of cores obtained from the same prismatic sample. Bidirectional coring is suitable for 38, 50 and 75 mm dia. See upgrading options.

The innovative transversal coring clamp system allows users to obtain cylindrical asphalt specimens in 38, 50 and 75 mm dia. This unique accessory (see accessories) ensures that samples, both 100 and 150 mm dia., are securely clamped whilst drilling is commenced to provide perfect specimens every time.

A unique, easy and intuitive cylindrical clamp accessory allows users to quickly and easily core asphalt specimen from cylindrical samples produced in the gyratory compactor up to 150 mm dia. (see accessories). The same coring can also be done, as alternative, with the KorBit machine model standardly supplied complete with adjustable clamp.

The Multi Core-Drill can be used as part of your Superpave performance based testing program.