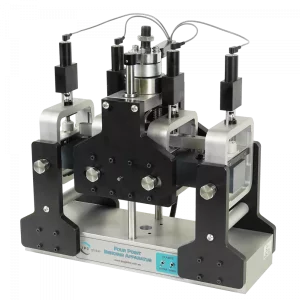

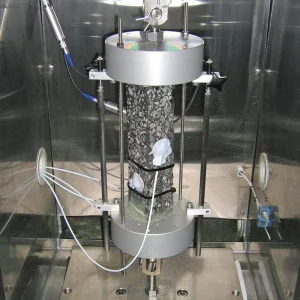

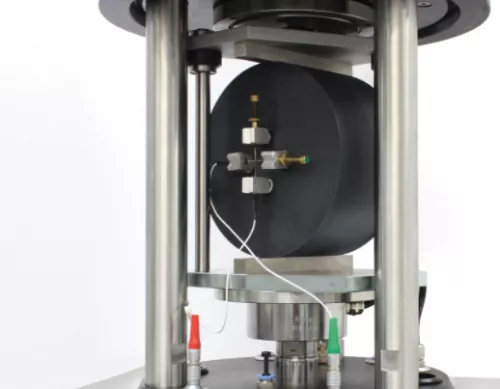

UTMs, AMPTs and modular asphalt testers perform a wide range of static and dynamic performance tests that need to be completed with suitable test kits. The testing accessories in this section allow you to perform tests covering a many material properties, including Stiffness/Dynamic Modulus, Fatigue Cracking, Thermal Cracking and Permanent Deformation tests.