A flexible standalone machine, the new Automatic Universal Tester with Touch Screen Digital Speed Control and Data Acquisition, or MULTILOADER, is the smart choice for road testing labs and generally for any test that requires displacement/speed control. In addition to CBR and Marshall tests, the 50kN capacity and fully variable speed of 0.05 to 51 mm/min enable many other applications, including quick undrained triaxial and unconfined/uniaxial soil tests, indirect tensile strength, IDEAL-CT, semi-circular bend, and Leutner shear tests.

The MULTILOADER tester has a rigid two-column structure with a height-adjustable upper crossbeam. An ergonomic cabinet contains the load jack, DC motor, and controls. The microprocessor makes sure that the test speed and travel are automatically controlled. Prior to the test, the operator can impose travel limits to automatically end the test.

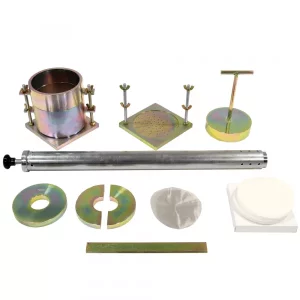

No external transducer is required for displacement measurement. The firmware enables the setting of up to 18 test profiles and the performance of transducer calibrations while storing data onboard. The user interface is a large integrated 7″ touchscreen graphic display, supplied with a stylus pen, which can show the real-time test graph and the transducer data and allows the testing data to be stored on a USB pen drive or downloaded through a LAN communication port in Controls, txt or ASCII format. All the accessories have to be ordered separately.. The machine has built-in data acquisition with six channels dedicated to two strain gauge load cells and two potentiometric linear transducers; one of each can be used during the test. The processing unit’s ability to regulate the speed in a closed-loop mode without having experienced speed calibration effects or tension fluctuation effects is a crucial feature.

The front panel is fitted with an emergency button for prompt stopping of the machine.