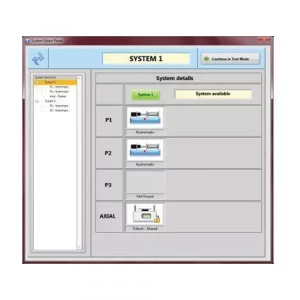

The AUTOTRIAX EmS software is a comprehensive and user-friendly interface between the operator and the testing system. Installed on a PC communicating with the system over a fast Ethernet connection, the software can be used to configure the system(s), calibrate transducers, specify test parameters, set system limits and control the system during a test, either manually or automatically. Due to the flexibility of the software, each triaxial system can either have its own, dedicated PC, or multiple systems can be run from one PC.

The software includes three modules with the following features:

- Device Management Software

- Test software

- Template for data processing

DEVICE MANAGEMENT SOFTWARE

– This base software is supplied as standard with the AUTOTRIAX EmS system

– Designed for setting up the configuration and allocation of the components of each triaxial system

– Up to 11 points of calibration can be recorded with automatic polynomial best fitting (up to 7th order)

– The calibration data of different transducers can be stored for the same channel and easily recalled when connected

– Full scale limits can be set for all the transducers and pressure/volume controllers to prevent over-travel and possible damage

– Management of Hydromatic 2 pressure/volume controllers and Tritech compression frames outside of testing procedures (e.g. controller tuning, water refilling of pressure controllers)

TEST SOFTWARE

All the test modules include the following basic features:

– Input of project, sample and test details and parameters

– Set up of test sequences, including selection of automatic or manual control

– Real-time data for all transducers are displayed throughout the test, as well as all calculated stresses, strains, ratios, volume change etc. Updated specimen dimensions are displayed at the end of each stage

– Graphical test data can be displayed on four separate user-definable graphs, each with up to six data series

– Manual control panel to control the solenoid valves, Hydromatic 2 and Tritech units before starting the test

– Transducer readings and zero-set options displayed in large font on a separate panel, enabling the user to easily view the readings from a distance

– Review option to look at data and graphs for tests already completed

– Data processing and reporting conforming to the relevant standards by quickly and easily importing test data into the Microsoft Excel AUTOTRIAX 2 triaxial template

– Test pause option (automatic or by the user) for conditioning/refilling the Hydromatic 2 pressure/volume controllers

– Simultaneous and independent control of axial stress (displacement or load controlled), cell pressure, back pressure, base pressure (in the Permeability Module) and air pressure (in the Unsaturated Soils Module)

– Alarm display when travel or capacity limits of the system components are reached

– Set up of additional limits to stop or to hold the stress/strain conditions during the test

EFFECTIVE and TOTAL STRESS

This software module, supplied as standard, includes manual or automatic control of saturation, consolidation (for effective stress tests) and shear stage, according to ASTM and BS Standards:

Saturation (ASTM D4767, ASTM D7181, BS 1377:Part 8)

Under manual control, three different options for running the stage are available:

– Increments of cell pressure only

– Increments of cell & back pressure

– Simultaneous ramps of cell and back pressure

Alternatively, automatic control can be selected to run the complete stage according to BS1377:8 Clause 5.3, BS1377:8 Clause 5.4 or ASTM 4767/7181.

Data monitoring and processing consists of:

– Multiple plot options including: cell pressure vs. pore pressure / B values; cell, back and pore pressure vs. time; volume change vs. time

– Summary table and plot of all the saturation steps performed

Consolidation (ASTM D4767, ASTM D7181, BS 1377:Part 8)

Automatic or manual isotropic consolidation with cell and back pressure targets set by the user

Data monitoring and processing consists of:

– Multiple plot options including: volume change and pore pressure dissipation vs. time

– Graphical fitting methods, according to the relevant standards, for the evaluation of the end of consolidation

CU/CD test monotonic shear (ASTM D4767, ASTM D7181, BS 1377:Part 8)

Automatic or manual shear stage (drained / undrained) using calculated or user-defined rate of strain and failure criteria in compression or extension (2)

Data monitoring and processing consists of:

– Multiple plot options including: deviator stress, volume change, pore pressure vs. axial strain; MIT or Cambridge stress path

UU test monotonic shear (ASTM D2850, BS 1377:Part 7)

Automatic or manual undrained shear stage in compression, with rate of strain and cell pressure input.

STRESS PATH MODULE (1) (2)

This optional software module is for the automatic or manual control of stress path stages, with independent control of axial and radial stresses. The module can be used together with the standard stages of saturation, isotropic consolidation and monotonic shear provided by the Effective Stress Test Module to carry out what is generally known as stress path testing. This package includes the following:

– Total stress ramps

– Back pressure ramps

– MIT stress ramps to target values of s and t

– Cambridge stress ramps to target values of p and q

– Ramps to target change in axial displacement/strain

– Ramps to target volume change

– User-defined independent ramps / hold of deviator stress, cell pressure and back pressure

Data monitoring and processing consists of:

– Multiple plot options including: total and effective stress, volume change, pore pressure vs. axial strain; MIT or Cambridge stress path

K0 MODULE (1) (2)

This optional software module is for the automatic or manual control of K0 stages, with closed-loop control of the cross-sectional area of the soil sample. The module can be used together with the standard test stages of saturation, isotropic consolidation and monotonic shear provided by the Effective Stress Test Module.

This package includes the following:

– Axial stress ramps with closed-loop control of radial stress to maintain the K0 conditions

– Radial stress ramps with closed-loop control of axial stress to maintain the K0 conditions

– K0 conditions, controlled via the continuous monitoring of volumetric strain and axial strain

– K0 conditions, controlled via the continuous direct measurement of the sample diameter by a local radial strain “on-sample” transducer

PERMEABILITY MODULE (1)

This optional software module is for the automatic or manual control of triaxial permeability stages in accordance with BS1377:Part 6. The module is used together with the standard test stages of saturation and isotropic consolidation provided by the Effective Stress Test Module to carry out triaxial permeability tests. This package includes the following:

– control and measurement of base pressure

– measurement of permeability under a constant hydraulic gradient

– measurement of permeability under a constant rate of flow

Data monitoring and processing consists of:

– Multiple plot options including: change of volume / mean flow rate vs. time

– Evaluation tools to calculate in real time the permeability from the mean flow plot

UNSATURATED SOIL MODULE (1)

This optional software module is for the automatic or manual control of specific stages for unsaturated soils.

The module is used together with the standard test stages of saturation, isotropic consolidation and monotonic shear provided by the Effective Stress Test Module to carry triaxial testing on unsaturated soils. Stress path stages can also be performed when the Stress Path Module has been purchased. This package includes the following:

– control and measurement of air pressure

– control of matric suction during consolidation, monotonic shear and stress path stages

– measurement of pore pressure using the axis translation method

– SWCC (soil water characteristics curve) test stage

Data monitoring and processing consist of:

– Multiple plot options including: matric suction/pressures vs. strain; matric suction vs. moisture content

– Display of all unsaturated related stresses throughout the test

CRS (Constant Rate of Strain) MODULE (1) (3)

This optional software module is for the automatic or manual control of specific stages for performing CRS (Constant Rate of Strain) consolidation test.

The module consists in the following stages:

– Saturation stage

– Consolidation loading stage

– Dissipation stage

– Consolidation unloading stage

This package includes the following:

– ramp to target of cell pressure during saturation stage

– measurement of base pore pressure

– axial strain ramps to target with constant test speed during consolidation stage

– closed-loop control of axial stress to mainain the base excess pressure ratio (Ru) target during consolidation stage

– closed-loop control of axial stress to mainain the load target during dissipation stage

Data monitoring and processing consist of:

– Multiple plot options including: Total stress/Effective stress vs. strain; axial load vs.strain; Cell pressure/Pore pressure vs. time

– Display of Cell pressure/Pore pressure ratio during saturation stage;

– Display of base excess pressure ratio (Ru) during consolidation stage;

– Display of Degree of Dissipation during dissipation stage;

UC (Unconfined Compression) MODULE (1) (4)

This optional software module is for the automatic or manual control of Unconfined Compression test.

The module allows to measures the unconfined compressive strength of cohesive soils using axial strain-controlled conditions. The test consists in Unconfined compression stage and includes:

– ramp to target of cell pressure during saturation stage

– measurement of base pore pressure

– axial strain ramps with constant test speed

Data monitoring and processing consist of:

– Multiple plot options including: axial load vs.strain; Total stress vs. strain

CBR (California Bearing Ratio) MODULE (1) (5)

This optional software module is for the automatic or manual control of California Bearing Ratio test.

The module allows to measures the bearing capacity of subgrade natural or compacted soil for design of flexible pavement using axial strain-controlled conditions.

(1) An additional license must be purchased to unlock this module

(2) A vacuum top cap and submersible load cell must be used for tests with stages in extension

(3) CRS cell or CRS adaptor for triaxial cell and base plate must be used for performing the test

(4) Upper and lower platens, transducer bracket and external load cell must be used for performing the test

(5) CBR penetration piston and CBR mould must be used for performing the test

TEMPLATE FOR DATA PROCESSING

Triaxial Template is Excel-based data processing software that has been specially designed for the AUTOTRIAX 2 testing system. Data for the entire test is imported at the click of a button, with individual worksheets created and completed automatically for each stage of the test. Test reports are generated conforming to the selected standard and can be printed.

– Automatic data importing

– Processing and reporting of results to EN or BS or ASTM standards

– Includes presentation of Mohr circles and failure envelope with manipulation tools

– Triaxial permeability results can be post-processed to calculate the permeability value

– Possibility to plot a combined stress path graph of total and effective Cambridge and MIT stress path parameters over the whole test

– Can process multiple types of test*:

Unconsolidated Undrained (UU) triaxial – single, set of 3 or multistage

Consolidated Undrained triaxial (CU) – single, set of 3 or multistage

Consolidated Drained triaxial (CD) – single, set of 3 or multistage

Triaxial permeability

– CU and CD tests with any type of stage can be processed:

Saturation

Isotropic consolidation

Monotonic shear

Unsaturated (soil/water curve)

Stress path

K0

*The types of test that can be processed depend on which modules of the AUTOTRIAX EmS software are licensed