Code:79-PV70502

AMPT Universal proving ring assembly, complete with 6 hexagonal gauge points

Code:79-PV70507

AMPT Consumables kit. Comprises: 24x AMPT Sample Target (Hexagonal Gauge points) 1x Selleys 5 Min Araldite 24mL 1x 9.75″”/3/32″” Rubber O-Ring 1x 100mm Sealing Rings (Pack of two) 2x 100mm Rubber Membranes”

Code:79-PV70617

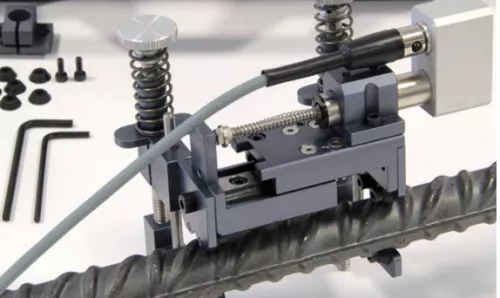

Uni-Axial Fatigue Gluing Jig – 75, 50 & 38mm Specimen Retro-fit Kit

Code:79-PV70618

Uniaxial Fatigue Tension platen (one piece) for 50mm diameter specimens

Code:79-PV71000

AMPT Pro – All-in-One Touch Screen PC Assembly

Code:79-PV71001

AMPT Pro compressor assembly, Max air flow 137 L/min, 8 Bar cap., 5 litres tank, with air dryer with molecular sever 230V/50Hz/1ph

Code:79-PV71002

AMPT Pro compressor assembly, Max air flow 137 L/min, 8 Bar cap., 5 litres tank, with air dryer with molecular sever 220V/60Hz/1ph

Code:79-PV71010

AMPT Pro On-Specimen LVDT Assy – IPC Guided SpringCore Black. Includes ILC Pod and LVDT Target Clamps x2

Code:79-PV71011

AMPT Pro On-Specimen LVDT Assy – IPC Guided SpringCore Blue. Includes ILC Pod and LVDT Target Clamps x2

Code:79-PV71012

AMPT Pro On-Specimen LVDT Assy – IPC Guided SpringCore Green. Includes ILC Pod and LVDT Target Clamps x2

Code:79-PV71211

AMPT 50mm Specimen Platen Kit (top & bottom platens set)

Code:79-PV71212

AMPT LVDT Gauge Point Fixing Jig 38mm Specimen Upgrade Kit

79-PV71213

AMPT LVDT Gauge Point Fixing Jig 50mm Specimen Upgrade Kit