78-PV0255

ILS device for internal angle measurement for Gyratory compactors, conforming to EN 12697-31, annex B. Complete with Excel Macro and PC connection cable

78-PV0250/10

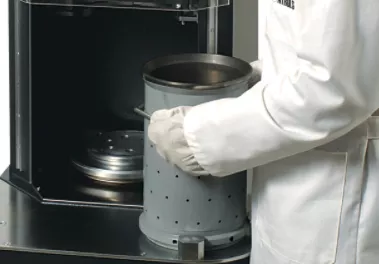

Hardened cylinder mould 150 mm dia. with holes for cold mix compaction. Complete with top and bottom plates

78-PV0250/11

Vertical force indicator, complete with 25kN load cell, base, spherical seat, load readout unit and calibration certificate

78-PV0250/13

Stainless steel wearing disc for 150mm dia. gyratory compactor mould

78-PV0250/14

Stainless steel wearing disc for 100mm dia. gyratory compactor mould

78-PV0250/2

Hardened cylinder mould 150 mm dia complete with top and bottom plates.

78-PV0250/3

Distance piece 150 mm dia x 50 mm for low samples

78-PV0250/4

Accessories to compact dia 100 mm specimens, required when 100mm cylinders (78-PV0250/5, 78-PV0250/8) are used. Mould not included.

78-PV0250/5

Hardened cylinder mould 100 mm dia complete with top and bottom plates.

78-PV0250/6

Distance piece 100 mm dia x 38 mm for low samples.

78-PV0250/8

Hardened cylinder mould 100 mm dia. with holes for cold mix compaction. Complete with top and bottom plates

78-PV20/SOF

PC software, suitable for Galileo standard gyratory compactor

78-PV20UP1

Shear measurement system, suitable for Galileo Standard gyratory compactor (to be specified at time of order)

78-PV20UP2

Integrated electromechanical extruder, suitable for Galileo standard gyratory compactor (To be specified at time of order) – Suitable for 100 and 150 mm dia. specimens

78-PV20UP3

Electronic balance, 30 kg. cap., 1 g resolution. To weight the sample and to calculate the density.Suitable for Galileo standard and Galileo Research gyratory compactors (To be specified at time of order)

78-PV20UP4

Traceable ACCREDIA certificate conforming to EN 12697-31 Ann. B (To be specified at time of order)