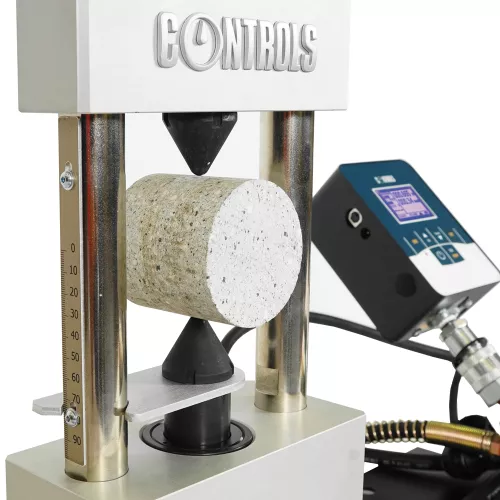

This apparatus, originally designed for soil mechanics test applications, can also be used to provide an infinitely variable constant pressure and is used in conjunction with the Hoek cell fit with the permeability end caps, for the investigation of the permeability of rock at high confining pressure, in the laboratory. The apparatus comprises: motorized hydraulic pump; honed piston/spring assembly; precision test gauge 0-3500 kPa range; cylindrical oil/water interchange vessel; valves; 2 kg of high viscosity oil.

The lateral pressure can be applied with the 32-D0558 Low friction pressure maintainer or, as alternative, with the 32-D7022/S sercomp S or 32-C7022/RCK Sercomp Rock, servo-hydraulic control console which is part of the Automatic Uniaxial and Triaxial test systems.

- Pressure range: 0 to 3500 kPa

- Overall dimensions: 310x300x390 mm

- Weight approx.: 16 kg

As alternative to oil-water constant pressure system 28-WF4312 it is possible to use new HYDROMATIC standalone closed loop pressure/volume controller:

- 28-WF45SG: powers 1 hydraulic pressure line and measures the associated volume change. Used for applying 1 level of pressure higher than atmospheric pressure.

- 28-WF45DG: powers 2 hydraulic pressure line and measures the associated volume change. Used for applying 2 levels of pressure higher than atmospheric pressure.

Typical configurations of Rock permeability test set

Manual Rock permeability system – Oil and water pressure apparatus

Code | Description | Q.ty |

28-WF4312 | Oil and water constant pressure apparatus | 1 |

28-WF0490 | Nylon tubing 6×4 mm dia., 20 m coil | 1 |

32-D0556(1) | Hoek cell NX size, 54.74 mm dia. x 100 mm | 1 |

32-D0556/3 | Permeability end caps for NX Hoek cell. Set of two. | 1 |

28-WF4191 | Connecting hose to the Hoek cell | 1 |

86-D1160 | Graduated glass burette 25 ml cap. x 1.1 ml div. | 1 |

86-D1445 | Support base 200×130 mm complete with rod 10 mm dia. x 500 mm | 1 |

86-D1451 | Double sleeve metal/glass | 1 |

32-D0558 | Low friction pressure maintainer | 1 |

32-C7022/S(2) | Sercomp Rock control console | 1 |

Automatic Rock permeability system – 1 level of pressure with HYDROMATIC standalone pressure / volume controller

Code | Description | Q.ty |

28-WF45SG | HYDROMATIC standalone closed loop pressure/volume

controller. Powers one hydraulic pressure line | 1 |

32-D0556/KIT | Hydraulic kit for Hudromatic stand-alone system with Hoex cell for rock permeability application | 1 |

32-D0556(1) | Hoek cell NX size, 54.74 mm dia. x 100 mm | 1 |

32-D0556/3 | Permeability end caps for NX Hoek cell. Set of two. | 1 |

28-WF4191 | Connecting hose to the Hoek cell | 1 |

86-D1160 | Graduated glass burette 25 ml cap. x 1.1 ml div. | 1 |

86-D1445 | Support base 200×130 mm complete with rod 10 mm dia. x 500 mm | 1 |

86-D1451 | Double sleeve metal/glass | 1 |

32-D0558 | Low friction pressure maintainer | 1 |

32-C7022/S(2) | Sercomp Rock control console | 1 |

Automatic Rock permeability system- 2 levels of pressure with HYDROMATIC standalone pressure / volume controller

Code | Description | Q.ty |

28-WF45DG | HYDROMATIC standalone closed loop pressure/volume

controller. Powers two hydraulic pressure lines | 1 |

32-D0556/KIT | Hydraulic kit for Hudromatic stand-alone system with Hoex cell for rock permeability application | 1 |

32-D0556(1) | Hoek cell NX size, 54.74 mm dia. x 100 mm | 1 |

32-D0556/3 | Permeability end caps for NX Hoek cell. Set of two. | 1 |

28-WF4191 | Connecting hose to the Hoek cell | 1 |

32-D0558 | Low friction pressure maintainer | 1 |

32-C7022/S(2) | Sercomp Rock control console | 1 |

(1) Other models are available. See Hock cell details

(2) An alternative to the manual model 32-D0558