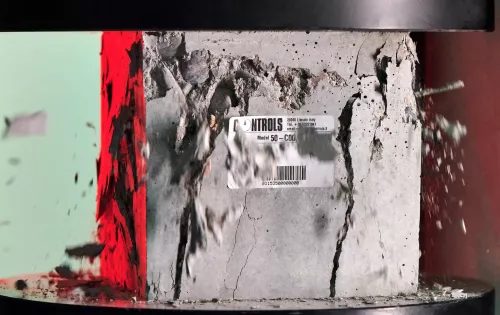

COMPACT-Line compression testers fulfil all the strict requirements of EN Standards (EN 12390-4, EN 772-1) in terms of load measurement accuracy, load rate application, compression platens hardness, flatness, parallelism and roughness. In addition, they are supplied with their traceable test certificates for load transfer verification (stability test) and for load measurement accuracy.

It is a proof of correct spherical seat behavior that is required for the initial self-alignment of the upper plate when first in contact with the specimen and and for subsequent restraint of movement until specimen failure as per specifications.