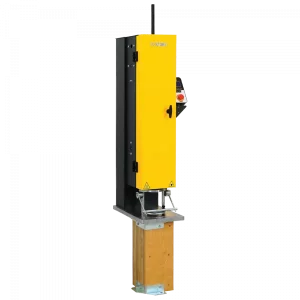

Asphalt mix needs to be compacted to get its optimal mechanical properties. Marshall impact compactors are the most common traditional methods, and they’re available both as manual compactors, requiring an operator manually lifting the hammer, and automatic compactors, automatically compacting the sample after a pre-set number of blows. As an alternative, vibrating hammers are also available.