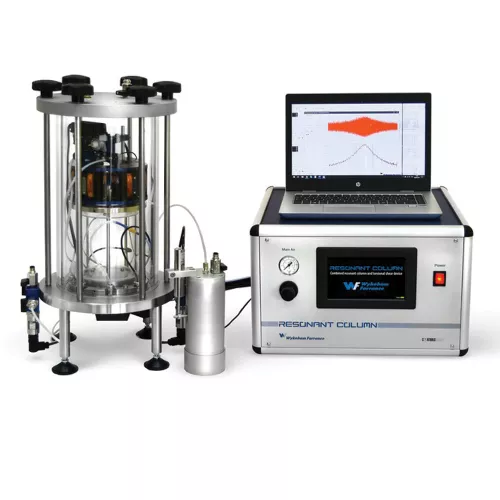

Wykeham Farrance’s Resonant Column is a versatile system that combines Resonant Column and torsional shear tests into one convenient device for evaluating Shear Modulus and Damping Ratio. It includes:

- current-driven motor that applies torsional load to the sample

- a series of transducers with signal conditioning

- cell and back pressure electro-pneumatic control system

- data logger.

How it works

- A cylindrical soil specimen is restrained at the base and dynamically excited at the top by means of an electrical motor generating torsional forces via eight drive coils encircling four magnets attached to a drive plate at frequencies of up to 300 Hz

- The fundamental mode of vibration is determined from the maximum amplitude of motion. Following test standard ASTM D4015, resonant frequency, shear wave velocity and shear wave modulus are calculated using elasticity theory.

- The corresponding shear strain is evaluated from the motion amplitude. Material damping can be determined from the half-power bandwidth or from a free-vibration decay curve, which is generated by shutting off the driving power.

- In the Torsional Shear test, the soil specimen is deformed cyclically at a low frequency (a maximum of 10 Hz), whilst continuously monitoring torque and deformation.

- From the torque-deformation curves, a relationship between average shear stress and average shear strain is obtained, which in turn provides the shear modulus and the damping ratio.

The system consists of the following components:

TRIAXIAL CELL

Stainless steel cell with acrylic transparent cylinder with 170 mm int. dia. x 200 mm ext. dia., including

channels for bottom and top drainages; internal floating frame for assembling the electrical

motor that applies the torsional load. Test accessories for 50 mm (or 38 mm available on request)

diameter specimens.

N°2 calibration bars kit + n°1 calibration weight.

MAIN CONTROL BOX, LAPTOP PC AND SOFTWARE

Compact unit connected to laptop PC contains all control, power supply as well as electrical and pneumatic

devices. This system also contains air actuators (I/P converters) and amplification equipment.

High resolution 7” color touchscreen display for cell, and pore pressure monitoring.

SENSORS

The sensor kit contains: Axial LVDT transducer, Volume Change Apparatus, three pressure transducers,

two Eddy current displacement sensors with high precision motorized proximity sensors positioning,

low noise MEMS accelerometer.

The complete system includes a high-quality PC supplied with pre-installed intuitive Windows-based software that allows you to perform both Resonant Column and Torsional Shear tests. The test stages are as follows:

SATURATION

Ramped increase of cell and back pressure is applied causing the air to dissolve for a complete saturation of the specimen. All the pressure readings are shown in real time using an intuitive high resolution colour display.

ISOTROPIC CONSOLIDATION

The confining pressure is applied through the cell pressure until the soil is consolidated, i.e. when pore pressure is dissipated, and volume change is negligible. The soil specimen is restrained at the bottom and dynamically excited at the top.

RESONANT FREQUENCY

Frequencies up to 300 Hz are increased automatically in “steady-state” mode by steps (RC discrete) or continuously (RC chirp), or in “free-decay” mode by only an initial frequency. Since the frequency of the input signal varies, the dynamic response of the specimen results in a varying motion amplitude. The secant shear modulus G is determined by the resonant frequency.

The damping ratio D can be evaluated with two methods:

- In the frequency domain, from the complete frequency response of the soil specimen (half-power bandwidth)

- In the time domain, from free-vibration decay curve that is generated by shutting off the driving power (logarithmic decrement method).

TORSIONAL SHEAR

The technique used is the input torsional rotation through a sinusoidal current applied to the coils.

Cyclic torque application in Torsional shear.