Shear Boxes and Accessories

Shear Boxes

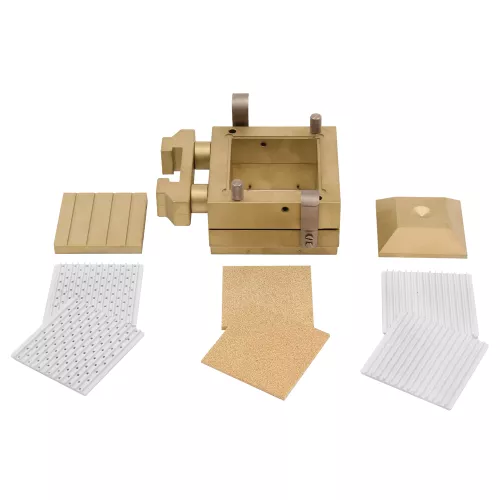

Round or square shear boxes manufactured from brass

Standards ASTM D3080 AASHTO T236 BS 1377:7 EN 17892-10

Shear box assemblies

These shear box assemblies are designed to be used with our 27-WF20D60 Digishear, 27-WF21A60 Autoshear and 27-WF21E80 Shearmatic shear testing machines.

Manufactured from brass and designed to contain the water that surrounds the specimen.

They consist of a square box with a rigid walled round or square hole complete with:

– adapter loading pad

– retaining plate

– 2 plastic grids

– 2 perforated plastic grids

– 2 bronze sintered porous plates.

Sample cutter and extrution dolly for sample preparation should be oreded separately (see accessories)

- Completely electromechanically operated

- Possibility to program user defined procedures as free combination of load and displacement (or combined) controlled cycles

- Completely electromechanically operated

- Conforming to EN 12697-33, 5.2 method and ASTM D8079

- 21” All-in-one touchscreen PC controlled , PC and software included

- Includes the compaction procedure defined in the brand new EN 12697-33 method 7.3, providing at the beginning a controlled displacement compaction which can grant a flat surface followed by a load compaction phase , which can replicate the real compaction on the road surface

- Base and foot adjustable heating system available as option

- Mould dimensions: 500 x 400, 500 x 300, 400 x 300, 300 x 300 and 320 x 260 mm, 195 mm height

- Compaction direction in the longest (major) mould dimension to obtain specimens of the proper length conforming to Standard

- Vertical balanced of sliding cover for easy access and complete three side view

- Maximum compaction load 30 kN

- User defined controlled linear speed up to 300 mm/sec and adjustable pause at the mould inversion point

- Ideal for producing test beams for 4-Point bending (EN 12697-24, EN 12697-26, AASHTO T321) and slabs down to 38 mm

- Vibrating roller option, adjustable from 10 to 50 Hz

- PRO-COMPACT* closed loop control slabs

- Customization of compacting cycle which can be saved and recalled from the database

*PRO-COMPACT closed-loop is an innovative mechanical and electronic control that combines orthogonality of the load, pendulum motion of the head and sinusoidal non-friction forward-reverse carriage movement. This results in an optimally compacted sample that features Planarity Regularity and hOmogeneity (PRO). The combined load/displacement compaction procedure provides at the beginning of the test a controlled displacement compaction, which can grant a flat surface of the compacted slab, followed by a load compaction phase, which can replicate the real compaction on the road surface.

- Box Material: Brass

- Grids and perforate grid material: Plastic

- Porous plate material: Sintered bronze

- Nominal samle dimension: 60 (square); 100 (square); 50 (round); 60 (round); 63.5 (round); 100 (round)

- Sample height: 20 mm

- Weight approx.: from 2.5 to 4 kg

Shear box accessories

The sample cutter and the extrusion dolly, necessary during the specimen preparation operations

Shear box accessories configurator

Required accessories for Shear Box

The required accessories, not supplied with the shear box, should be ordered separately.

The sample cutter and the extrusion dolly, necessary during the specimen preparation operations, are designed to be easily fitted within the shear box.

They are available for both square and round shear box.

Single parts of the shear box assembly can be ordered as spare parts.

Slotted Steel Weights

Used for consolidation (oedometers), shear testing machines and other applications.

Standards ASTM D8079

27-WF0270/A to 27-WF0277/A

Used for consolidation (oedometers), shear testing machines and other applications.

Manufactured from steel. Protected against corrosion. Accurately calibrated assuring the specified tolerance.

Four weight sets are avaialble, for coverring the majority of the Standard loading sequence:

- CONSOLIDATION: 64 kg or 80 kg

- SHEAR: 37.5 kg or 34 kg

Single weight can be ordered separatelty (see accessories)

Consolidation test

| 26-WF0230/C2 – 64 kg | |

| 27-WF0270/A – 0.250 kg | 2 |

| 27-WF0271/A – 0.500 kg | 1 |

| 27-WF0272/A – 1 kg | 1 |

| 27-WF0273/A – 2 kg | 1 |

| 27-WF0274/A – 4 kg | 1 |

| 27-WF0275/A – 8 kg | 7 |

Consolidation test

| 26-WF0230/D2 – 80 kg | |

| 27-WF0270/A – 0.250 kg | 2 |

| 27-WF0271/A – 0.500 kg | 3 |

| 27-WF0272/A – 1 kg | 1 |

| 27-WF0273/A – 2 kg | 1 |

| 27-WF0276/A – 5 kg | 3 |

| 27-WF0277/A – 10 kg | 6 |

Shear test

| 27-WF0230/C3 – 37.5 kg | |

| 27-WF0270/A – 0.250 kg | 2 |

| 27-WF0271/A – 0.500 kg | 2 |

| 27-WF0272/A – 1 kg | 2 |

| 27-WF0273/A – 2 kg | 3 |

| 27-WF0274/A – 4 kg | 3 |

| 27-WF0275/A – 8 kg | 2 |

Shear test

| 27-WF0230/C4 – 34 kg | |

| 27-WF0272/A – 1 kg | 2 |

| 27-WF0273/A – 2 kg | 1 |

| 27-WF0277/A – 10 kg | 3 |