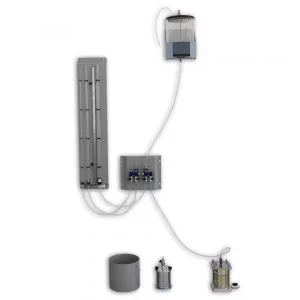

Permeability (hydraulic conductivity of soil) is a very important factor in the study of the natural behaviour of soil with respect to water flow. This section includes different soil permeability equipment conforming to ASTM, AASHTO, EN and BS Standards for constant-head and falling-head permeability test methods for road base and subbase soils.

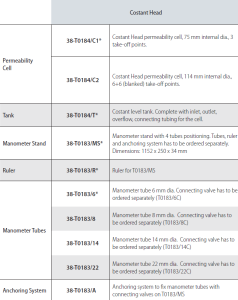

Models

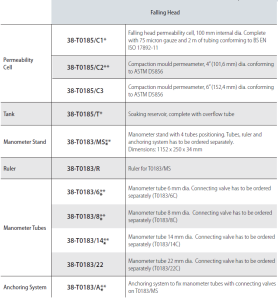

Models

Shearing motion: Electromechanically driven at 4°

Shearing motion: Electromechanically driven at 4°